When choosing a motor for applications ranging from electric tools to robotics, understanding the difference between AC (Alternating Current) and DC (Direct Current) motors is crucial. These two types of motors power countless devices, from household appliances to industrial machinery, and each offers unique advantages depending on the use case. In this educational guide, we explore the key differences between AC and DC motors, their applications, and why DC motors are increasingly popular in industries worldwide, particularly from DC motor manufacturers in China. Whether you’re sourcing custom DC motors or exploring DC motor wholesale options, this article will equip you with the knowledge to make informed decisions and drive inquiries to leading suppliers.

AC motors operate on alternating current, where the electric current periodically reverses direction. This allows AC motors to leverage the alternating voltage from power grids, making them a staple in large-scale industrial and household applications. Common types include:

Synchronous AC Motors: The rotor spins in sync with the AC supply’s frequency.

Induction AC Motors: The rotor is driven by an electromagnetic field induced by the stator, widely used in fans, pumps, and compressors.

AC motors are known for their durability and ability to handle high-power tasks, making them ideal for continuous, heavy-duty operations.

DC motors run on direct current, where the current flows in one direction, providing consistent power. Key types include:

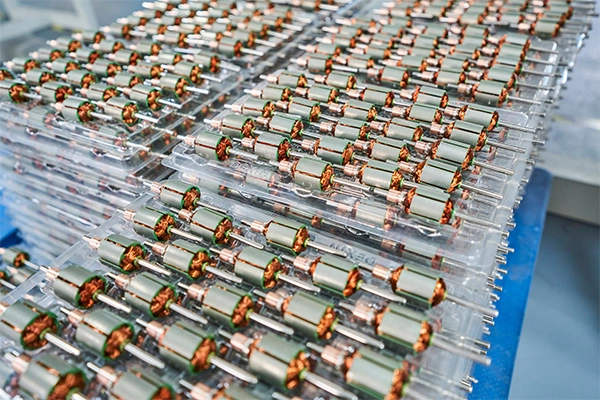

Brushed DC Motors: Use brushes to transfer current to the rotor, as seen in models like the RS 380 DC motor.

Brushless DC Motors (BLDC): Employ electronic commutation for higher efficiency and lower maintenance, popular in robotics and electric vehicles.

DC motors excel in applications requiring precise speed control and compact designs, driving demand for custom DC motors from DC motor manufacturers in China.

AC Motors: Powered by alternating current, typically from a wall outlet or industrial power grid. The alternating nature allows them to handle high-voltage, high-power applications like HVAC systems.

DC Motors: Powered by direct current, often from batteries or DC power supplies. This makes DC motors, such as the 540 DC motor, ideal for portable devices like electric tools and drones.

AC Motors: Feature a stator and rotor, with induction motors relying on electromagnetic induction. They often have simpler designs but may require additional components like capacitors for starting.

DC Motors: Include a stator, rotor, and either brushes (in brushed models like the RS 380 DC motor) or electronic controllers (in BLDC motors). The presence of brushes can lead to maintenance needs, while brushless designs reduce wear.

AC Motors: Speed is typically tied to the AC frequency, requiring variable frequency drives (VFDs) for precise control. They offer consistent torque for steady-state operations.

DC Motors: Provide excellent speed and torque control, making them ideal for applications needing variable speeds, such as robotics or electric vehicles. Custom DC motors can be tailored for specific torque requirements.

AC Motors: Generally more robust and require less maintenance due to fewer moving parts in induction designs. However, efficiency can vary based on load and frequency.

DC Motors: Brushless DC motors offer superior efficiency and lower maintenance compared to brushed models. For example, DC motor wholesale suppliers in China provide BLDC motors with long lifespans for cost-effective solutions.

AC Motors: Dominate in industrial settings, powering large machinery like conveyor belts, pumps, and compressors. They’re suited for applications with consistent power demands.

DC Motors: Excel in compact, variable-speed applications. The RS 380 DC motor is popular in power tools, while the 540 DC motor is used in automotive systems and robotics. DC motor China suppliers cater to diverse industries with tailored solutions.

Durability: Built for continuous operation in harsh environments.

Cost-Effective for Large Systems: Lower initial costs for high-power applications.

Grid Compatibility: Easily integrates with standard AC power supplies.

Limited Speed Control: Requires additional equipment like VFDs for variable speeds.

Size and Weight: Often larger, making them less suitable for portable devices.

Precision Control: Excellent for applications requiring variable speeds and torque, such as robotics and electric vehicles.

Compact Design: Models like the RS 380 DC motor and 540 DC motor are lightweight and ideal for small devices.

High Efficiency: Brushless DC motors, popular in DC motor wholesale markets, offer superior energy efficiency.

Maintenance for Brushed Models: Brushed DC motors require regular maintenance due to brush wear.

Power Limitations: Less suited for extremely high-power applications compared to AC motors.

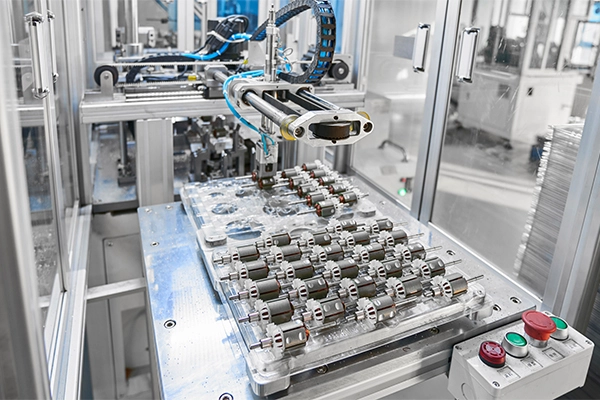

The global demand for DC motors is surging, driven by trends in electrification, automation, and renewable energy. DC motor manufacturers in China, such as those offering custom DC motors, are at the forefront of this growth. Key reasons include:

Electric Vehicles (EVs): DC motors, particularly BLDC models, are critical for EV propulsion and auxiliary systems.

Robotics and Automation: The precision of DC motors supports advanced robotics, with models like the 540 DC motor enabling compact, high-torque solutions.

Energy Efficiency: Brushless DC motors reduce energy consumption, aligning with sustainability goals.

Customization: DC motor China suppliers provide tailored solutions, meeting specific industry needs from medical devices to consumer electronics.

Industrial Machinery: Powering pumps, fans, and conveyors in manufacturing plants.

HVAC Systems: Driving air conditioners and heating units in commercial buildings.

Household Appliances: Found in washing machines, refrigerators, and air purifiers.

Electric Tools: The RS 380 DC motor powers drills and saws due to its compact size and high torque.

Automotive Systems: The 540 DC motor is used in window regulators and seat adjusters.

Robotics and Drones: Brushless DC motors provide precision for automated systems and UAVs.

Consumer Electronics: DC motors drive devices like electric toothbrushes and smart home gadgets.

Selecting between AC and DC motors depends on your application:

Choose AC Motors for high-power, continuous-duty tasks in industrial or grid-connected environments.

Choose DC Motors for compact, variable-speed applications requiring precision, such as robotics or portable devices. For tailored solutions, explore custom DC motors from DC motor manufacturers in China.

To source high-quality motors, consider DC motor wholesale suppliers who offer competitive pricing and certifications like ISO9001, CE, and RoHS. Leading manufacturers can provide detailed specifications and support for your project.

When sourcing DC motors, Ningbo Dexin (Mglory) Motor Co., Ltd. stands out as a premier choice. Based in Ningbo, China, Mglory is a leading manufacturer of micro-special DC motors, offering a diverse portfolio including the RS 380 DC motor, 540 DC motor, and brushless models like the BLDC-4815. Their advantages include:

Customization Expertise: Mglory provides custom DC motors tailored to specific torque, speed, and size requirements, ideal for robotics, automotive, and smart home applications.

Quality Assurance: Certified with ISO9001, CE, RoHS, and EMC, Mglory ensures reliable, high-performance motors that meet global standards.

Sustainability Focus: Guided by their MARBLE values (Make Customer Successful, Act as Owner, Remain Financially Strong, Benefit the Community, Lead for Environment), Mglory prioritizes eco-friendly practices.

Global Reach: With advanced production facilities and a skilled technical team, Mglory exports worldwide, offering competitive DC motor wholesale solutions.

Diverse Portfolio: From brushed DC motors (e.g., MGLORY DC-RS 775) to high-voltage servo motors, Mglory caters to varied industries with precision and efficiency.

For businesses seeking innovative, reliable, and sustainable DC motor solutions, Mglory is a trusted partner.

This is the first one.