The application of DC motors for robots is at the core of modern robotics, enabling precise movements, high torque, and efficient performance in everything from robotic arms to line follower robots. DC motors for robots, particularly robot gear motors and high torque DC motors for robots, are essential for applications requiring accuracy and reliability.

DC motors used in robots operate on direct current, typically powered by batteries, offering precise control and compact design. These motors come in two main types:

Brushed DC Motors: Use mechanical brushes for current transfer, ideal for cost-effective applications like simple rs 380 motor dc motor robot projects but requiring maintenance.

Brushless DC Motors (BLDC): Utilize electronic commutation for higher efficiency and durability, perfect for advanced robotics requiring dc motor position control.

The application of DC motors for robots leverages their versatility, making them ideal for tasks from precise positioning to high-torque movements in walking robots with DC motors.

Robots demand motors that deliver precision, efficiency, and compact size. DC motors for robots excel in these areas, enabling dynamic movements in applications like dc motor for robot car or dc motor for line follower robot. Manufacturers like Mglory DC motor China company provide motors that meet the rigorous demands of robotics, ensuring seamless performance in diverse projects. They also offer dc motor wholesale options for bulk procurement.

DC motor position control is a key advantage in robotics, allowing precise movements for tasks like picking, placing, or navigating. Robot gear motors enhance this precision by providing controlled torque at low speeds, ideal for applications like robotic arms or dc motor robot projects.

High torque DC motors for robots deliver the power needed for heavy tasks, such as lifting in industrial robots or walking in humanoid robots. Their compact size ensures they fit into space-constrained designs, making them perfect for 540 dc motor applications in dc motor for robot car projects.

DC motors for robots, especially BLDC models, minimize energy loss, extending battery life in mobile robots like dc motor for line follower robot. This efficiency is critical for autonomous robots operating in remote or continuous tasks.

Brushless DC motors used in robots reduce wear by eliminating brushes, resulting in longer lifespans and minimal maintenance. This durability is essential for robotics applications in demanding environments, from industrial automation to educational projects. Some applications also utilize low voltage servo motor technology for enhanced control and efficiency.

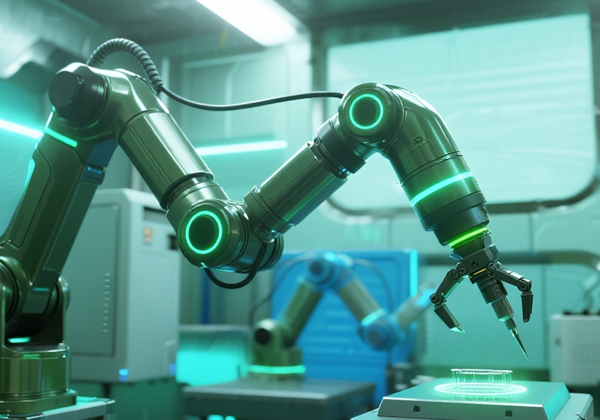

DC motors for robots power robotic arms in manufacturing, assembly, and research. DC motor position control ensures precise movements for tasks like welding or component placement, enhancing productivity and accuracy.

DC motor for line follower robot applications relies on robot gear motors for precise navigation along predefined paths. These motors provide the low-speed torque needed for smooth, accurate tracking in educational and industrial settings.

DC motor for robot car projects, popular in hobbyist and educational robotics, uses compact DC motors for propulsion and steering. These motors offer the speed and control needed for agile, responsive movement.

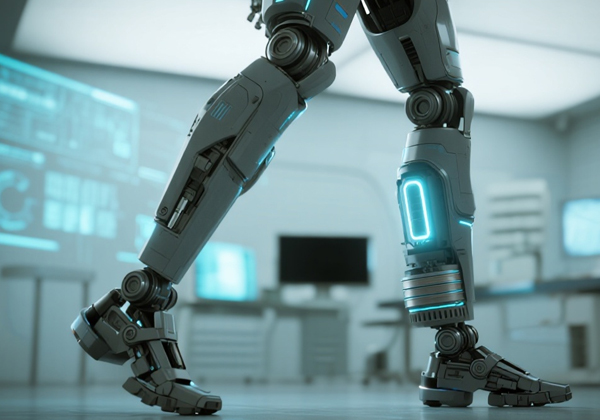

Walking robots with DC motors require high torque DC motors for robots to power leg mechanisms. These motors enable stable, dynamic movements in humanoid robots or quadrupeds used in research and entertainment.

DC motors provide the necessary power to the joints of the robotic arms, enabling highly accurate and minimally invasive procedures. Similarly, in rehabilitation robots, DC motors drive the joints to assist patients in regaining mobility and strength through controlled and repetitive movements. These motors ensure smooth and precise operation, which is essential for the delicate and complex tasks performed in medical settings.

Selecting the right DC motor for robots depends on your project’s requirements:

Application Type: Choose high torque DC motors for robots for heavy tasks like walking or lifting, or low-power motors for lightweight applications like dc motor for line follower robot.

Precision Needs: Opt for dc motor position control with BLDC or geared motors for tasks requiring high accuracy.

Size and Weight: Select compact motor DC robot solutions to fit small robot designs without compromising performance.

Customization Needs: For unique robotics projects, seek custom DC motors from trusted suppliers like Mglory, who offer tailored solutions for specific torque, speed, or mounting requirements.

When sourcing motors, prioritize DC motor wholesale suppliers with certifications like ISO9001, CE, and RoHS to ensure quality and reliability.

High-quality DC motors used in robots ensure reliability, precision, and efficiency in demanding applications. Leading manufacturers, such as Ningbo Dexin (Mglory) Motor Co., Ltd., use advanced production techniques and rigorous testing to deliver motors that meet global standards. Certified with ISO9001, CE, RoHS, and EMC, Mglory’s dc motors for robots are designed for the rigorous demands of robotics innovation.